In a world where consumer preferences constantly evolve, innovation is key to capturing consumer attention and ensuring product integrity. Discovered the Future of Tobacco Packaging with Advanced Laminates. These innovative laminates are designed to elevate tobacco product packaging, offering durability, style, and eco-friendliness. With advanced materials and technology, they keep tobacco fresher for longer while reducing environmental footprint. From enhanced protection against moisture to customizable designs, these laminates meet evolving consumer and industry demands.

Real life challenges:

- Barrier Performance and Flexibility: Barrier properties need to be balanced to block moisture, oxygen, and gases while maintaining flexibility.

- Print Compatibility: The laminate surface should works with flexography or gravure printing methods without affecting print quality or adhesion.

- Adhesive Selection: Most of the adhesives do not bond laminate layers effectively, do not work with printing inks, and maintain weak barriers.

- Material Selection: The right laminate materials is hard to choose for barrier, strength, and heat resistance is quite difficult while also considering recyclability, cost, and sustainability.

- Sealing Performance: Packaging must be done only after complete sealing, to maintain product freshness, especially in high-speed production.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Innovative solutions:

- Multi-layer laminates with nanotechnology-enhanced barrier coatings improve moisture and gas resistance while maintaining flexibility.

- Advanced plasma treatments and surface coatings like UV and Anti-Static coatings can ensure compatibility with various printing methods without compromising print quality or adhesion

- Innovative adhesive formulations, such as solvent-free or water-based adhesives, offer strong bonding while remaining compatible with printing inks and meeting regulatory requirements.

- Advanced sealing technologies, such as ultrasonic or laser sealing, ensure consistent and reliable seals during packaging, even in high-speed production environments.

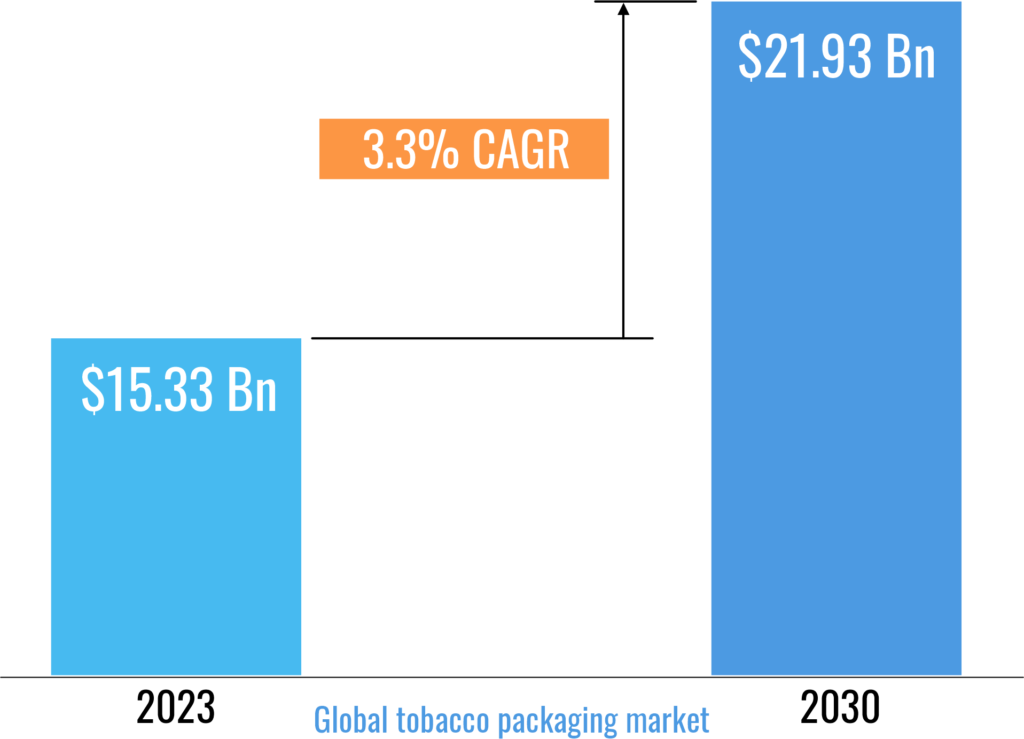

Market research:

Key players:

Some of the leading key players are

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Technology Intelligence

- Market Research

- Patent Landscape

- Technology gap analysis

- Design Patent Search

- Portfolio Analysis

- Freedom to operate

- Bio Sequence Search

- Innovation pipeline identification

- Chemical Structure Search

- Patent Invalidity Search

- Manufacturers Search/ Supplier search

- Patent Licensing Services

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.